Introduction

Organizing the asset inventory of a laboratory is crucial for ensuring operational efficiency and reducing costs. A well-maintained inventory helps in managing assets effectively, facilitates audits, and mitigates risks associated with asset management.

Step-by-Step Process to Organize Laboratory Asset Inventory

Follow these steps to streamline your laboratory asset inventory:

1. Conduct an Initial Inventory Assessment

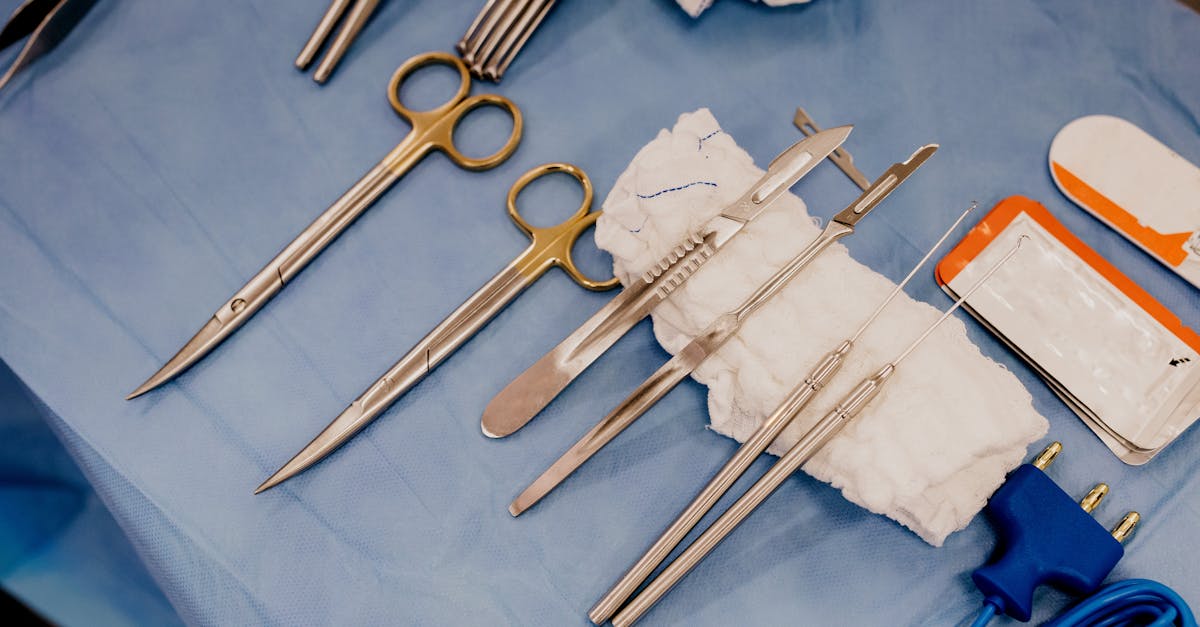

Evaluate your current inventory by identifying all assets within the laboratory, including equipment, tools, and supplies. This assessment sets the foundation for your inventory management system.

2. Categorize Your Assets

Organize your assets into categories based on their function, usage frequency, or department. This categorization simplifies tracking and management.

3. Implement an Asset Management System

Utilize an asset management platform, like Ordomind Assets, to track and manage your inventory. Ensure that all assets are logged into the system with detailed information.

4. Develop a Checklist for Regular Maintenance

To maintain your inventory, create a checklist that includes:

- Monthly inventory checks

- Routine maintenance schedules for equipment

- Updating asset information in the management system

- Training staff on asset handling and reporting

5. Schedule Regular Audits

Establish a schedule for regular audits to verify the accuracy of your inventory. This helps in identifying discrepancies and ensuring accountability.

Practical Example: Organizing a Laboratory Inventory

Consider a research laboratory that needs to organize its assets:

Step 1: The lab manager conducts an initial inventory check, listing all assets including microscopes, centrifuges, and reagents.

Step 2: The assets are categorized into equipment, consumables, and tools.

Step 3: The lab implements Ordomind Assets, logging each item with its category, condition, and responsible personnel.

Step 4: A checklist for maintenance is developed, and staff are trained to conduct monthly reviews.

Step 5: Quarterly audits are scheduled to ensure the integrity of the inventory data.

Key Performance Indicators (KPIs) for Asset Management

To measure the effectiveness of your asset inventory management, consider tracking the following KPIs:

- Inventory Accuracy: Percentage of assets correctly accounted for in the system.

- Mean Time Between Failures (MTBF): Average time between asset failures.

- Mean Time to Repair (MTTR): Average time taken to repair an asset after a failure.

- Audit Time: Time taken to complete an inventory audit.

- Percentage of Assets Without Assigned Responsibility: Helps in identifying accountability gaps.

Common Mistakes and How to Avoid Them

When managing laboratory assets, it’s easy to make mistakes that can lead to inefficiencies. Here are common errors and tips to avoid them:

- Inadequate Categorization: Ensure assets are categorized logically to simplify management.

- Ignoring Regular Updates: Regularly update the inventory system to reflect new acquisitions or disposals.

- Poor Training of Staff: Provide ongoing training to ensure that all staff understand how to use the asset management system effectively.

- Neglecting Audits: Schedule and conduct audits regularly to maintain inventory accuracy.

Conclusion

Organizing your laboratory asset inventory is not just about tracking items; it's about creating a system that enhances efficiency, accountability, and cost-effectiveness. By following the outlined steps, utilizing KPIs, and avoiding common pitfalls, laboratories can significantly improve their asset management practices.